When it comes to high-heat applications, choosing the right sealant is crucial for ensuring durability and performance. Enter high temperature silicone sealant—a versatile solution designed to withstand extreme temperatures while providing a reliable bond. Whether you’re working on automotive repairs, home improvement projects, or industrial applications, this specialized sealant stands out for its unique properties. Let’s dive into what makes high temperature silicone sealants essential tools in various settings and how they can benefit your next project.

What is a High Temperature Silicone Sealant?

High temperature silicone sealant is a specialized adhesive designed to endure extreme thermal conditions. Unlike regular silicone, this type can withstand temperatures that range from -65°F to over 600°F. Its unique formulation makes it ideal for high-heat environments.

This sealant remains flexible even under stress, allowing it to expand and contract without losing its bond. It’s resistant to moisture and various chemicals, making it suitable for demanding applications.

Typically available in tubes or cartridges, high temperature silicone can be easily applied with a caulking gun. The curing process occurs as the solvent evaporates, forming a solid yet elastic layer that adheres well to multiple surfaces like metal, glass, and ceramics.

Whether you’re sealing gaps around exhaust systems or protecting components in engines, this versatile sealant is engineered for reliable performance where other materials may fail.

Types of High Temperature Silicone Sealants

High temperature silicone sealants come in various types, each designed for specific applications. One common type is the room-temperature vulcanizing (RTV) silicone. It cures at ambient temperatures and can withstand extreme heat, making it ideal for automotive or industrial uses.

Another variant is the one-part high-temperature silicone. This option simplifies application as it requires no mixing and cures quickly upon exposure to air. It’s perfect for quick repairs in high-heat areas.

Two-part silicones are also available, offering greater flexibility and strength once fully cured. They require careful mixing but provide a robust bond suitable for aerospace or manufacturing settings.

There are specialty formulations that resist chemicals or have added features like UV stability. These sealants cater to niche needs while ensuring durability under challenging conditions. Each type serves its purpose effectively within high-heat environments.

Common Applications for High Temperature Silicone Sealants

High temperature silicone sealants are incredibly versatile and find their place in various industries. One of the most common applications is in automotive manufacturing. They effectively bond engine components, gaskets, and exhaust systems due to their resistance to heat and chemicals.

In the construction sector, these sealants are essential for sealing joints around fireplaces and chimney installations. Their ability to withstand extreme temperatures makes them an ideal choice for preventing leaks.

Another significant application is in electronics. High temperature silicone sealants protect high temperature silicone sealant for ovens sensitive components from thermal stress during operation.

They also play a vital role in aerospace engineering by securing parts that endure high heat during flight operations. Whether it’s ovens, furnaces, or industrial equipment, these sealants ensure durability under pressure while maintaining structural integrity across numerous applications.

Benefits of Using High Temperature Silicone Sealants

High temperature silicone sealants offer exceptional durability in extreme environments. These sealants can withstand temperatures ranging from -75°F to over 500°F, making them ideal for high-heat applications.

Their flexibility is another significant advantage. Unlike traditional adhesives, they maintain their elasticity even after curing. This allows them to expand and contract with thermal fluctuations without losing adhesion.

Water resistance is a key benefit as well. High temperature silicone sealants create a robust barrier against moisture, protecting your projects from potential damage or deterioration.

Additionally, these sealants are resistant to various chemicals and UV light. This resilience ensures that they won’t degrade over time when fashion exposed to harsh conditions.

Ease of application adds to the appeal. They can be applied using standard caulking tools and cure quickly, which helps save time on projects while providing long-lasting results.

Factors to Consider When Choosing a High Temperature Silicone Sealant

When selecting a high temperature silicone sealant, consider the maximum temperature rating. Different products withstand varying degrees of heat. Knowing your application’s specific requirements helps ensure optimal performance.

Next, check for flexibility and adhesion properties. A sealant needs to expand and contract with temperature changes without losing its bond. Look for formulations that offer strong adhesion to the materials you’re working with.

Another key factor is curing time. Some projects may require faster curing options while others can accommodate longer drying periods. Assess your timeline and choose accordingly.

Review environmental resistance features. Ensure the sealant can withstand exposure to chemicals or moisture if your application demands it. This will enhance durability in harsh conditions and prolong service life.

How to Properly Apply and Cure High Temperature Silicone Sealants

Proper application of high temperature silicone sealant is crucial for optimal performance. Start by ensuring the surfaces are clean and dry. Remove any dirt, dust, or old sealant residues to create a strong bond.

Cut the nozzle at a 45-degree angle to control the flow of the sealant effectively. This will help you apply it neatly in joints and seams.

When applying, maintain consistent pressure on the caulking gun to avoid gaps or bubbles. Smooth out the bead with a finger or tool dipped in soapy water for an even finish.

Curing time varies depending on environmental conditions. Generally, allow at least 24 hours before exposing it to high temperatures or moisture.

Keep in mind that humidity can affect curing times; higher humidity may speed up curing while low humidity might slow it down. Always check manufacturer guidelines for specific instructions related to your chosen product.

Safety Precautions When Working with High Temperature Silicone Sealants

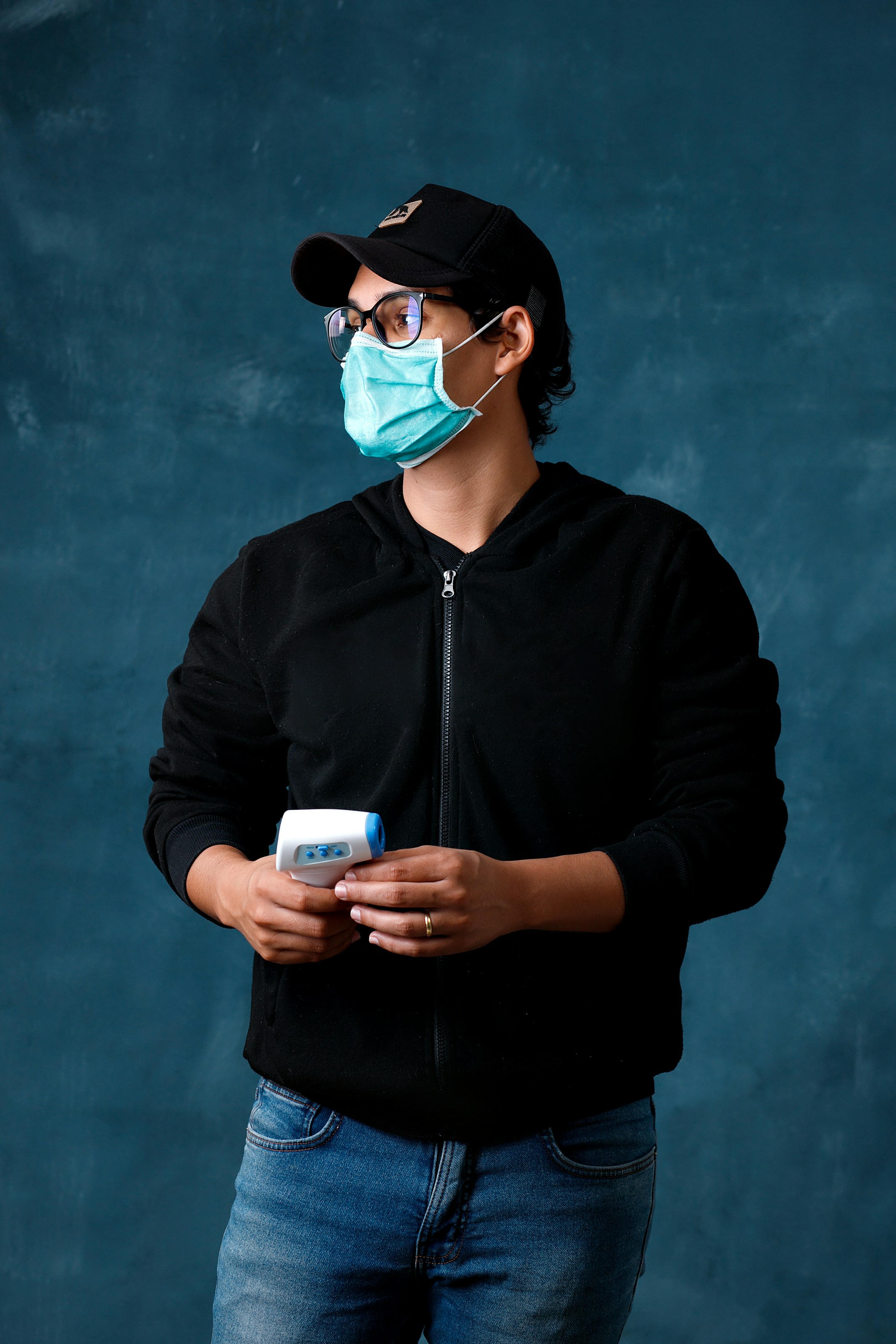

When working with high temperature silicone sealants, safety should always be a priority. Start by wearing proper personal protective equipment (PPE). Gloves and goggles can shield your skin and eyes from irritation.

Ensure you work in a well-ventilated area. Silicone sealants release fumes that may cause respiratory discomfort. Adequate airflow helps mitigate this risk.

Keep flammable materials away from your workspace. Some components of these sealants can ignite if exposed to heat or flames.

Follow the manufacturer’s instructions on application and curing times closely. Ignoring guidelines could lead to improper adhesion or hazardous situations.

Avoid contact with food surfaces until the product is fully cured. It ensures no harmful chemicals leach into consumables during use. Prioritizing these precautions can help maintain a safe environment while achieving effective results with high temperature silicone sealants.

Conclusion

High temperature silicone sealants are essential for various applications where heat resistance is critical. They provide durability, flexibility, and reliability in environments prone to extreme temperatures. Understanding the different types available allows you to select the right one for your specific needs.

These sealants find their place in automotive components, industrial machinery, and even household repairs that require thermal resilience. The benefits of using high temperature silicone sealant extend beyond mere adherence—it optimizes performance and longevity under stress.

When choosing a high temperature silicone sealant, consider factors such as cure time, maximum operating temperature, and compatibility with other materials. Proper application techniques can significantly impact effectiveness; ensure surfaces are clean and dry before applying the product.

Safety should never be overlooked when working with any chemicals. Always wear appropriate protective gear to minimize exposure during application.

With this knowledge at hand, you’re better equipped to tackle projects requiring reliable sealing solutions that stand up to both heat and pressure. Your choice of a high temperature silicone sealant could make all the difference in achieving lasting results.